It’s a Friday evening, July 26, when the champagne pops. Finally, after more than a decade of court battles, the country’s biggest class-action lawsuit was settled with a R5-billion agreement in the Johannesburg high court. Former miners who have contracted silicosis and tuberculosis can now be compensated by the companies they toiled for in the depths of the Earth.

But this is where the hard work begins: finding the men who gave their youth to the mines, were paid a pittance and returned to their homes — scattered across Southern Africa — with very little health left. Many have since died and their families are left to struggle without breadwinners.

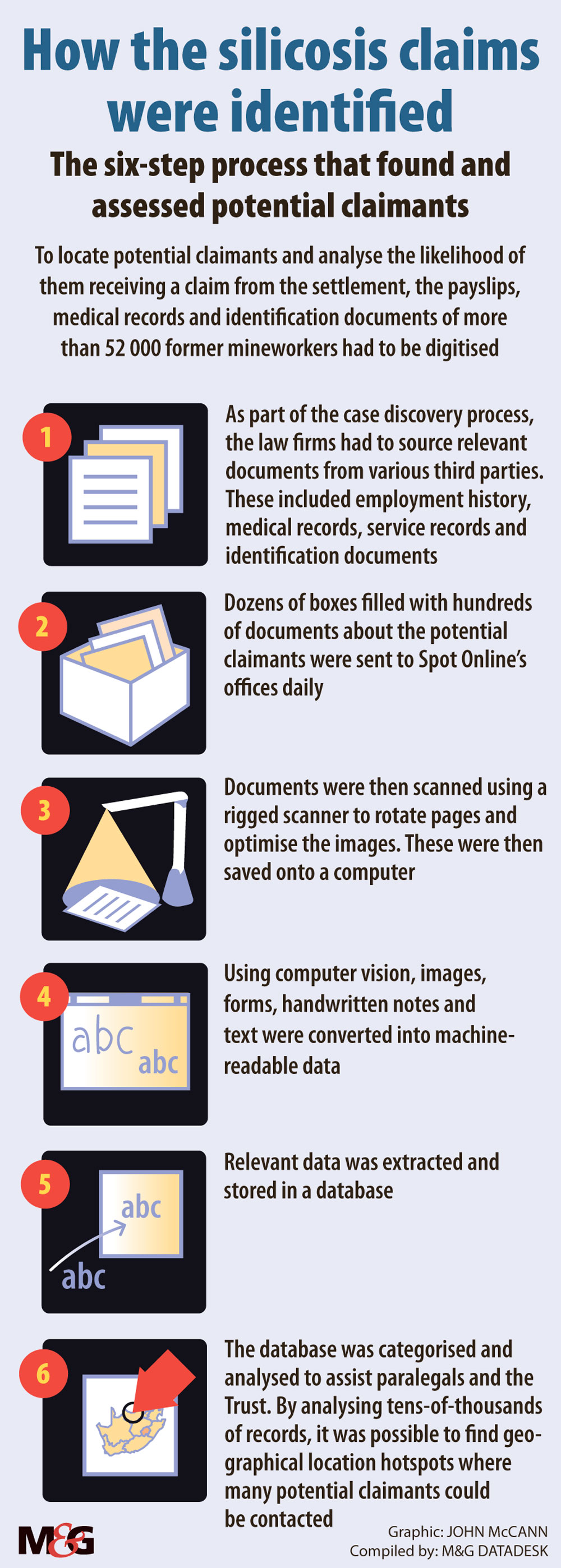

This is a story about those people and the technology that was used to build this case — and, ultimately, compensate those affected by chronic lung diseases.

Vama Jele, who chairs the Southern African Miners’ Association, says that mineworkers have been waiting years for compensation. He says that the biggest challenge facing them is dealing with the office of the compensation commissioner for occupational diseases, run by the department of health.

“It’s supposed to pay out to ex-mineworkers. But to date, these mineworkers — even if they put all documents forward to their claim — can’t get their money,” says Jele, who also represents the Swaziland Migrant Mineworkers Association.

The Mine Health and Safety Act makes the mines responsible for safe and healthy workplaces. But since it was enacted in 1996, no mining company has compensated former employees who suffer from silicosis.

In 2012, however, Richard Spoor Attorneys requested the class certification of more than 15,000 prospective class members at the Johannesburg High Court. After years of proceedings, the court handed down its judgment in 2016. Among the rulings, was the need to examine individual cases of affected miners at their place of employment. This was unprecedented in the South Africa’s legal history.

Legal representatives of the mineworkers — namely Richard Spoor Attorneys, Abrahams Kiewitz Attorneys and the Legal Resources Centre — now had to determine whether each represented mineworker had, in fact, been affected by silicosis and tuberculosis and whether the mines themselves were responsible. The workers' IDs, medical records, employment history and a variety of additional documents were needed.

“We needed to find clients for the class action,” says George Kahn from Richard Spoor. The legal team then had to build a database — one that could locate, verify and, ultimately, help to compensate the miners and their families.

It’s a common tactic in the legal industry for corporate attorneys to overwhelm small legal firms with information. These days, however, with advances in technology, firms are able to analyse and make sense of physical, unstructured information much faster and more accurately.

“It’s no longer an effective strategy to dump tons of boxes of documentation on us with the hope that we’re going away. That’s probably the last thing they want to do now,” Kahn says.

Ken Gliddon from Cape Town assisted with building this database. The techie says the team received as many as 25 boxes of workers’ records every day. Each box contained copies of about 70 former mineworkers’ documentation. Gliddon even rigged a scanner to automatically digitise the documents more quickly.

“What we’re trying to do there is to tie all those bits together. Some of it’s meaningless: some are particularly relevant, like payslips and IDs,” Gliddon says.

Using computer vision — artificial intelligence that can recognise text characters and handwriting — the model he built quickly riffles through information and extracts relevant data. Gliddon, together with his team at A Spot of Innovation, is the technical partner of the legal firms who represented the miners.

Kahn adds that: “It would’ve cost us a small fortune to employ an army of paralegals, who would’ve taken years to produce the same results manually.”

“By having machines that can do that en masse, it’s very easy to quickly work out who can and who can’t qualify [for compensation] just based on service records,” Gliddon says. “The more data the model gets the smarter it gets.”

By collecting workers’ data, the team managed to build a wealth of knowledge about more than 50,000 potential claimants, a number that is growing larger by the day.

Claimants’ information gathered so far shows that Lesotho is home to an overwhelming number of former mineworkers. Maseru is home to 1,954 potential claimants, while the Leribe and Berea regions have 1,402 and 1,307, respectively.

Kahn says the data helps the team to tell a story about where the former mineworkers had to move throughout their lives, as well as to track whether mineworkers tend to migrate to a particular mine from another. But, more critically, it helps the team to find out where they or their families are located today.

The high court ruled that compensation will be managed and paid through the Tshiamiso Trust. The analysis is critical to the trust, which will be using it to find claimants. It’s also useful for what Gliddon calls “compensation triage”. He says that, in terms of classification, the model can rapidly determine the amount of supporting evidence each individual has for their claim in the early stages of the application process.

“The trustees are going to want to know where they need to go look for these people to find them in order to make sure whoever is eligible to get money gets paid their money,” Kahn says.

Gliddon has also incorporated machine learning to build what he calls a “compensation triage system”. By analysing individuals’ information, the system categorises potential claimants into weak, medium and strong — which indicates the former miner’s likelihood of being successful in his application process. This allows the trust to prioritise those claimants who have a high probability of being successful in their case.

They have even trained a machine learning model to the point that it can differentiate between different doctors and specialists by picking up patterns in their diagnoses. By doing this, the team can isolate how different doctors read different symptoms. “So we can go to that doctor and say to them: ‘You always pick out TB where nobody else can see TB. What is it that you’re looking for that nobody else can bloody see?’” he says.

Going forward, this wealth of knowledge collected over the years will now be built on. Thousands of lung X-ray scans have been identified with silicosis and classified accordingly. Gliddon explains that these are now being studied to build triage systems that use machine learning to identify a miner’s probability of having silicosis in seconds rather than days or weeks.

Workers’ records are furthermore being analysed to help identify high-risk work areas in mines that have not been recognised before — essentially developing preventive solutions that could save the lives of the half-a-million people working in the mines today.

This story is by Jacques Coetzee, who is an Adamela Data Fellow at the Mail & Guardian. His position is funded by the Indigo Trust.

Web-design assistance was provided by Mitso Qalaba.

Photos from Eswatini were taken by Delwyn Verasamy and those from Lesotho by Paul Botes.

Hiram Alejandro Durán was responsible for the video footage. Code used for this project can be found on Github and more coverage about silicosis and the settlement can be found on the Mail & Guardian.